Progettato con estrema cura nell’integrazione di ogni singolo componente, garantisce accuratezza, ripetibilità ed affidabilità

Misurare con estrema velocità qualsiasi tipo di superficie in modo automatico, rendendo rapida e produttiva l’attività di Controllo Dimensionale, in particolare quando sono richieste misure ricorrenti.

La potenza della “programmazione collaborativa” sia del robot che del Software di Ispezione rende gli impianti disponibili per le misure in-line in brevissimo tempo, aumentando considerevolmente l’efficienza dell’intero processo di misura.

La gamma QBOX è realizzata per adattarsi alle diverse necessità di misura, con particolare attenzione sia alle dimensioni che alla geometria dei componenti da misurare. Il posizionamento e il successivo scarico dei componenti sono facili da eseguire e possono essere effettuati anche in maniera automatizzata, laddove richiesto.

QBOX è disponibile con i seguenti pack opzionali: Visual Pack, Safety Pack, Comfort Pack, Programmazione Offline ed Easy Load, per soddisfare ogni tipo di esigenza.

Tutte le celle della gamma QBOX sono integrabili con i più avanzati software di ispezione per adeguarsi agli standard aziendali. Gli output della misura sono configurabili in modo tale da essere gestiti dai sistemi SPC presenti in azienda per l’analisi statistica dei processi.

Progettato con estrema cura nell’integrazione di ogni singolo componente, garantisce accuratezza, ripetibilità ed affidabilità

Misurare con estrema velocità qualsiasi tipo di superficie in modo automatico, rendendo rapida e produttiva l’attività di Controllo Dimensionale, in particolare quando sono richieste misure ricorrenti..

La potenza della “programmazione collaborativa” sia del robot che del Software di Ispezione rende gli impianti disponibili per le misure in-line in brevissimo tempo, aumentando considerevolmente l’efficienza dell’intero processo di misura.

La gamma QBOX è realizzata per adattarsi alle diverse necessità di misura, con particolare attenzione sia alle dimensioni che alla geometria dei componenti da misurare. Il posizionamento e il successivo scarico dei componenti sono facili da eseguire e possono essere effettuati anche in maniera automatizzata, laddove richiesto.

QBOX è disponibile con i seguenti pack opzionali: Visual Pack, Safety Pack, Comfort Pack, Programmazione Offline ed Easy Load, per soddisfare ogni tipo di esigenza.

Tutte le celle della gamma QBOX sono integrabili con i più avanzati software di ispezione per adeguarsi agli standard aziendali. Gli output della misura sono configurabili in modo tale da essere gestiti dai sistemi SPC presenti in azienda per l’analisi statistica dei processi.

L' elevata flessibilità del sistema, combinata insieme al semplice e facile utilizzo, rende il QBOX adatto a molteplici applicazioni in diversi settori. QBOX integra le più avanzate tecnologie disponibili sul mercato e fornisce eccellenti prestazioni, elevati standard qualitativi e massima affidabilità.

Soluzione ultra compatta, collaborativa e versatile. QBOX MiniCobot è adatto alle misure di oggetti di piccole e medie imensioni, inseribile in un ambiente di lavoro dove l’operatore può rimanere a contatto con il dispositivo.

SuperficieQualsiasi tipo di superficie collaborativa senza l’utilizzo di spray. |

PesoFino a 100 kg |

DimensioneFino a 1000 mm |

| Dimensioni (WxLxH) | 1.7m x 0.8m x 2.2m |

| Tecnologia di Misura | Croci laser multiple |

| Software di ispezione | Incluso nella fornitura di base, il pacchetto può essere scelto tra differenti tipologie. Programmazione dei cicli di misura offline e di ispezione completamente integrata. |

| Software di controllo | Incluso nella fornitura di base. Ambiente di controllo integrato per una programmazione semplice e rapida, con processo di autoapprendimento. |

| Alimentazione elettrica | Monofase con neutro, 230V, 50Hz, 16A |

| Automazione | Robot antropomorfo a 6 assi controllati. Su richiesta asse aggiuntivo. |

Soluzione compatta, collaborativa e versatile. QBOX Cobot è adatto alle misure di oggetti di medie dimensioni, inseribile in un ambiente industriale, nel quale si voglia isolare l’area di misura dal resto del processo, pur mantenendo i vantaggi di una tecnologia collaborativa.

SuperficieQualsiasi tipo di superficie collaborativa senza l’utilizzo di spray. |

PesoFino a 100 kg |

DimensioneFino a 1000 mm |

| Dimensioni (WxLxH) | 2.11m x 2.81m x 2.62m. |

| Tecnologia di Misura | Croci laser multiple |

| Software di ispezione | Incluso nella fornitura di base. Programmazione dei cicli di misura offline completamente integrata. |

| Software di simulazione | Incluso nella fornitura di base. Ambiente di simulazione integrato per una programmazione semplice e rapida con processo di autoapprendimento. |

| Alimentazione elettrica | Monofase con neutro, 230V, 50Hz, 16A. |

| Automazione | Robot antropomorfo a 6 assi controllati. Su richiesta asse aggiuntivo. |

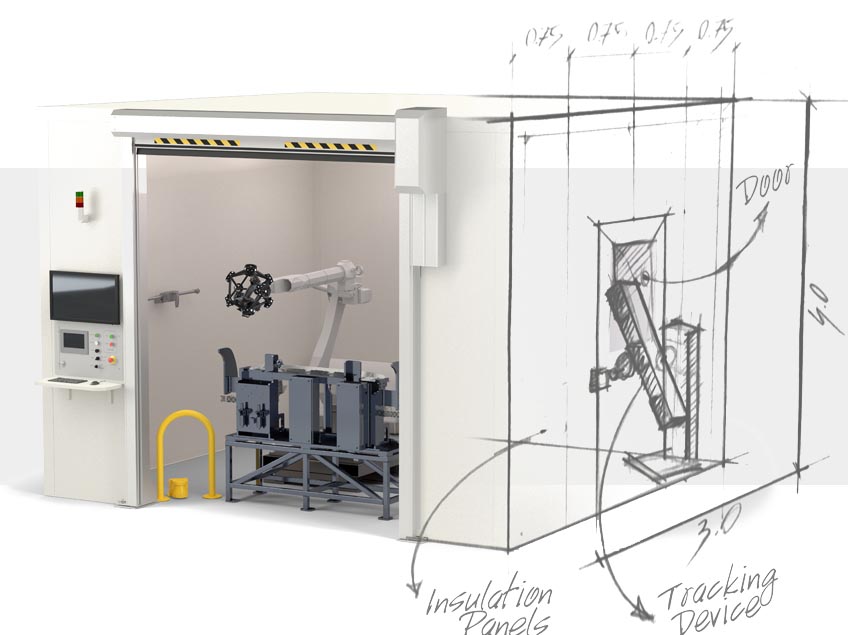

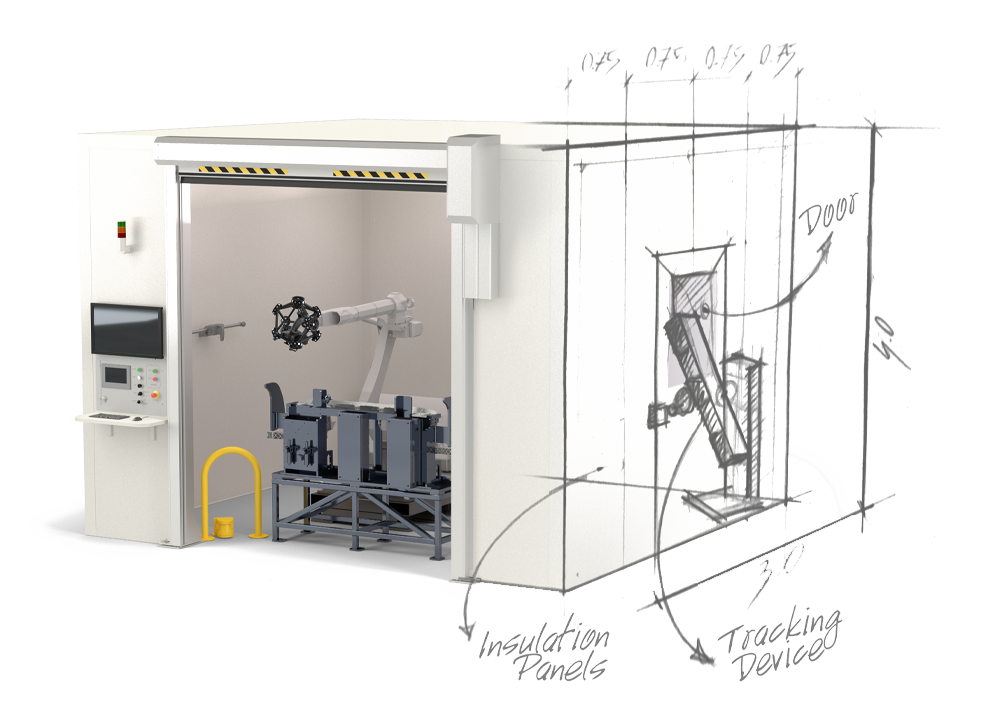

Ideale per componenti di medio grandi dimensioni. Dotato di porta scorrevole per isolare completamente la cella di misura dall’ambiente circostante, può essere inserito in pressoché tutti i contesti industriali produttivi.

SuperficieQualsiasi tipo di superficie, anche non collaborativa, senza l’utilizzo di spray oppacizzante o marker |

PesoFino a 1000 kg |

DimensioneFino a 1100 mm senza l’utilizzo di markers |

| Dimensioni (WxLxH) | 4.0m x 3.0m x 2.6m |

| Tecnologia di Misura | Laser-ottica |

| Software di ispezione | Incluso nella fornitura di base, il pacchetto può essere scelto tra differenti tipologie. Programmazione dei cicli di misura offline e di ispezione completamente integrata |

| Software di simulazione | Incluso nella fornitura di base. Simulatore dell’ambiente integrato per programmare in modo virtuale |

| Alimentazione elettrica | Trifase con neutro, 400V, 50Hz, 32A |

| Automazione | Robot antropomorfo con 6 assi controllati. Su richiesta asse aggiuntivo |

Soluzione industrial, dotata di box con robot di tipo tradizionalee di sensore laser. Ideale per componenti di medie e grandi dimensioni. Dotato di porta scorrevole per isolarecompletamente la cella di misura dall’ambiente circostante, può essere inserito in pressoché tutti i contesti industriali produttivi. Il sensore Laser porta con se tutti i vantaggi di questa tecnologia di acquisizione.

SuperficieQualsiasi tipo di superficie, anche non collaborativa senza l’utilizzo di spray opacizzante o marker. |

PesoFino a 1500 kg |

DimensioneFino a 2000 mm senza l’utilizzo di markers. |

| Dimensioni (WxLxH) | 4.7m x 4.7m x 2.6m. |

| Tecnologia di Misura | Croci laser multiple - ottiche |

| Software di ispezione | Incluso nella fornitura di base. Programmazione dei cicli di misura offline completamente integrata. |

| Software di simulazione | Incluso nella fornitura di base. Simulatore dell’ambiente integrato per programmare in modo virtuale. |

| Alimentazione elettrica | Trifase con neutro, 400V, 50Hz, 32A. |

| Automazione | Robot antropomorfo a 6 assi controllati. Su richiesta asse aggiuntivo. |

Soluzione industrial, progettata e realizzata sulla base delle specifiche esigenze del cliente. Ideale per componenti di qualunque dimensione. Tutti gli elementi sono integrati in un unico ambiente di misura che ha lo scopo di integrarsi al massimo con il processo produttivo. Sono previsti dispositivi di carico scarico automatici, operazioni di misura in ombra a quelle di carico e scarico, sistemi di supporto del componente da misurare integrati ed a chiusure automatiche per rendere tutta l’applicazione “one button”.

SuperficieQualsiasi tipo, riflettente o nera senza l'uso di spray. |

PesoA seconda dei componenti da misurare. |

DimensioneA seconda dei componenti da misurare. |

| Dimensioni (WxLxH) | A seconda delle esigenze. |

| Tecnologia di Misura | Croci laser multiple - ottiche |

| Software di ispezione | Incluso nella fornitura di base. Programmazione dei cicli di misura offline completamente integrata. |

| Software di simulazione | Incluso nella fornitura di base. Simulatore dell’ambiente integrato per programmare in modo virtuale. |

| Alimentazione elettrica | Trifase con neutro, 400V, 50Hz, 32A. |

| Automazione | Robot antropomorfo a 6 assi controllati. Su richiesta asse aggiuntivo. |

Si prega di compilare tutti i campi richiesti nel form sottostante

Si prega di compilare tutti i campi richiesti nel form sottostante